Location:

Energy Recovery in HVAC is a common expression used when energy that would otherwise be wasted is transferred back into the system.

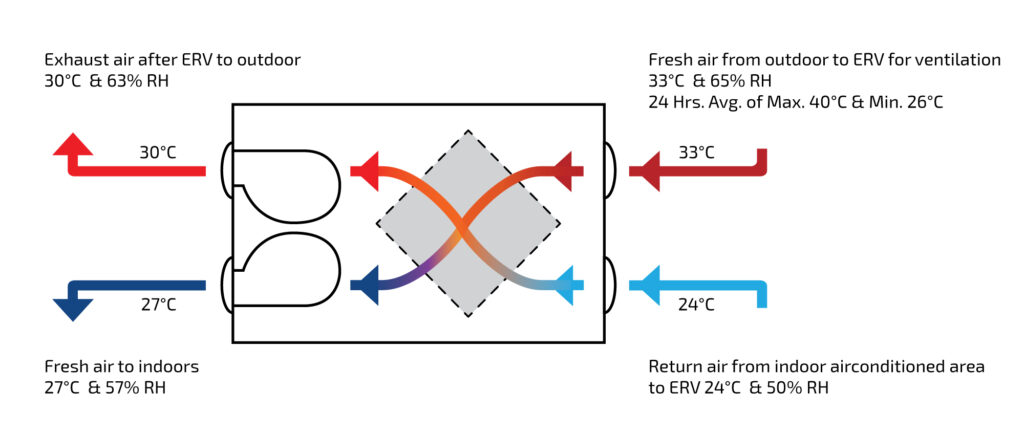

Whenever fresh outdoor air is introduced into a building, it results in the same volume of air being exhausted. This conditioned exhaust air carries with it heat which can be recovered and transferred to the incoming fresh air. This process is called ‘energy recovery’ or ‘heat recovery’

An Energy Recovery Ventilator (ERV) involves the process of incoming outdoor fresh air and exhausting indoor air being passed through a heat exchange module. The heat (energy) is transferred from one airstream to the other airstream, without the different airstreams mixing.

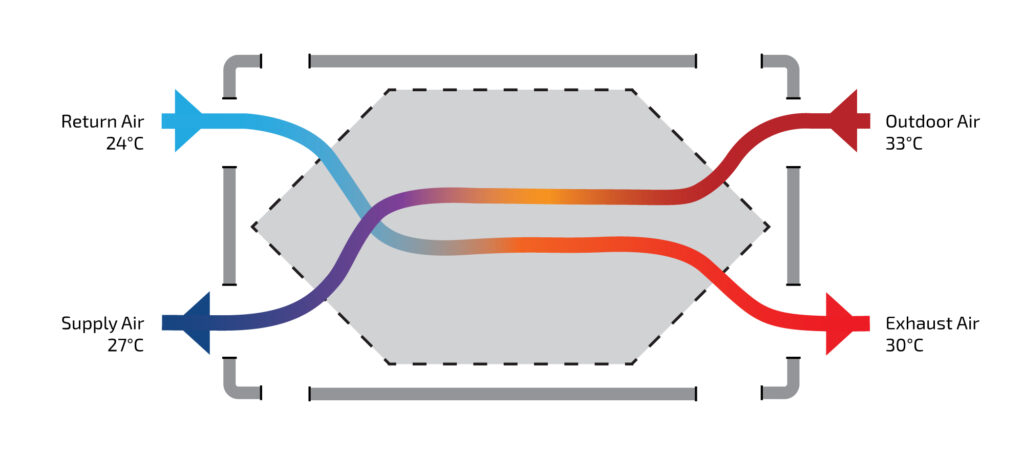

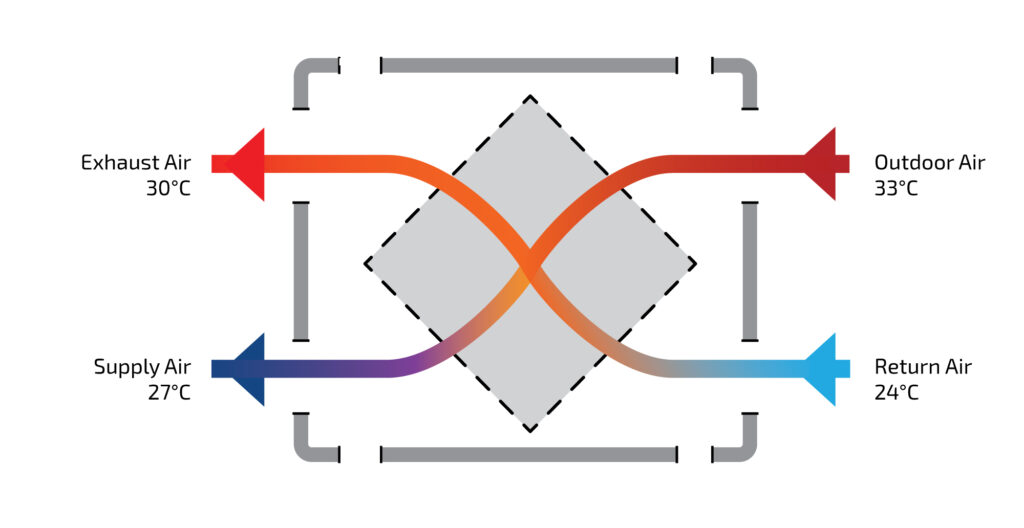

Air temperatures shown in these examples are indicative only.

The common air-to-air Energy Recovery processes are:

Plate Heat Exchanger

Plate heat exchangers are the preferred option in ventilation systems

where any ‘circulation’ of air is undesirable and the incoming and outgoing airstreams need to be completely isolated and no moisture or odours

can be transferred. Plate exchangers can recover energy in both

winter and summer.

Counterflow Plate Heat Exchangers

At the core of a Counterflow module is a stack of aluminum or plastic plates, which create airflow channels. In Counterflow units the channels are arranged to ensure parallel opposing airflows and thus maximize the heat energy exchange. In winter the highly heat-conductive plates transfer heat from the exhaust airstream to the supply airstream. The reverse occurs in summer, when the warmer entering air is cooled.

Cross-Flow Plate Heat Exchangers

In a Crossflow module, the air channels are arranged so that the airflows cross over one another. These heat exchangers are also increasingly seen in industrial ventilation and extraction systems as the design can be substantially larger in size than Counterflow units.

The spacing between the plates can be of various widths and this is important in systems in which the air may be contaminated or in commercial systems which allows high airflows without a high static pressure drop.

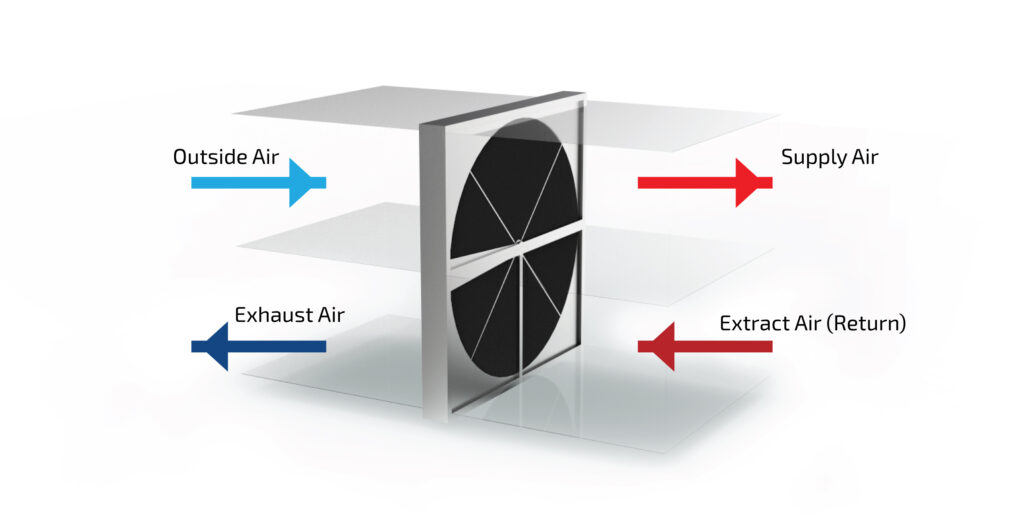

Rotary Heat Wheel

Rotary heat exchangers have a wheel-like construction, usually made of aluminum foil, featuring countless small channels through which the air passes and transfers heat to this storage mass.

The heat wheel rotates between two air streams of the incoming supply air, and the outgoing exhaust air.

Through this process, in winter conditions, most of the exhaust air heat is transmitted to the storage mass. This warmed half of the wheel rotates until it is in the path of the cooler supply air, to which it transmits its heat. Consequently, the supply air enters the building at a significantly higher temperature.

In summer, the principle operates in reverse. The exhaust air is cooler than the incoming air. The rotor stores the lower temperature of the exhaust air and so cools the warm air entering from outside.

Read more: https://armcor.com.au/news/energy-recovery-ventilation-2/

Disclaimer: The data and information contained in Armcor Air Solution technical specification sheets are representative of expected performance. They are derived from aggregated specifications of the individual components used in the equipment and not from verified laboratory testing. This should only be used for evaluating your specific application and clients have the sole responsibility of satisfying themselves that the goods or services are suitable for any specific use.